Prototyping, an essential phase for validating your design

Technical and market validation

Prototyping is mainly used to verify the technical feasibility of the product, following its study by our RD center. In addition to validating the technical aspects, prototyping is also necessary to define your complete usecase, including the internal scenario, for better team buy-in.

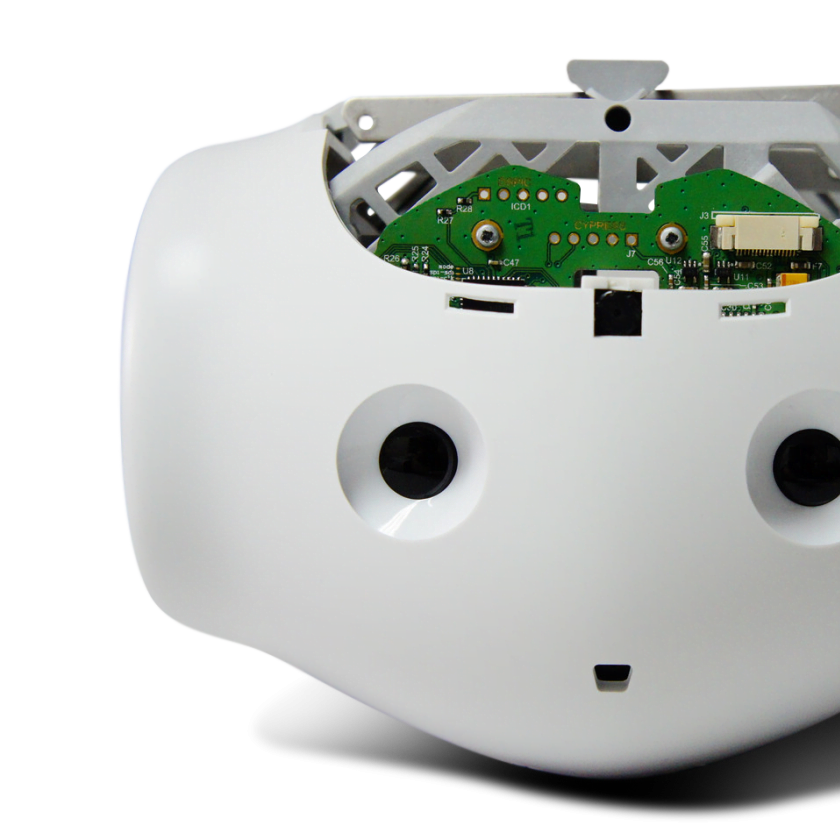

Functional prototyping, the gateway to industrialization

This phase generally consists of two stages:

Your role is very important. Adjustments and fine-tuning take place between the two prototyping phases, until the final prototype is validated. For some complex products, the number of iterations may exceed 2. Your validation of the F prototype will enable you to move on to the next phase, in particular the launch of tooling production.

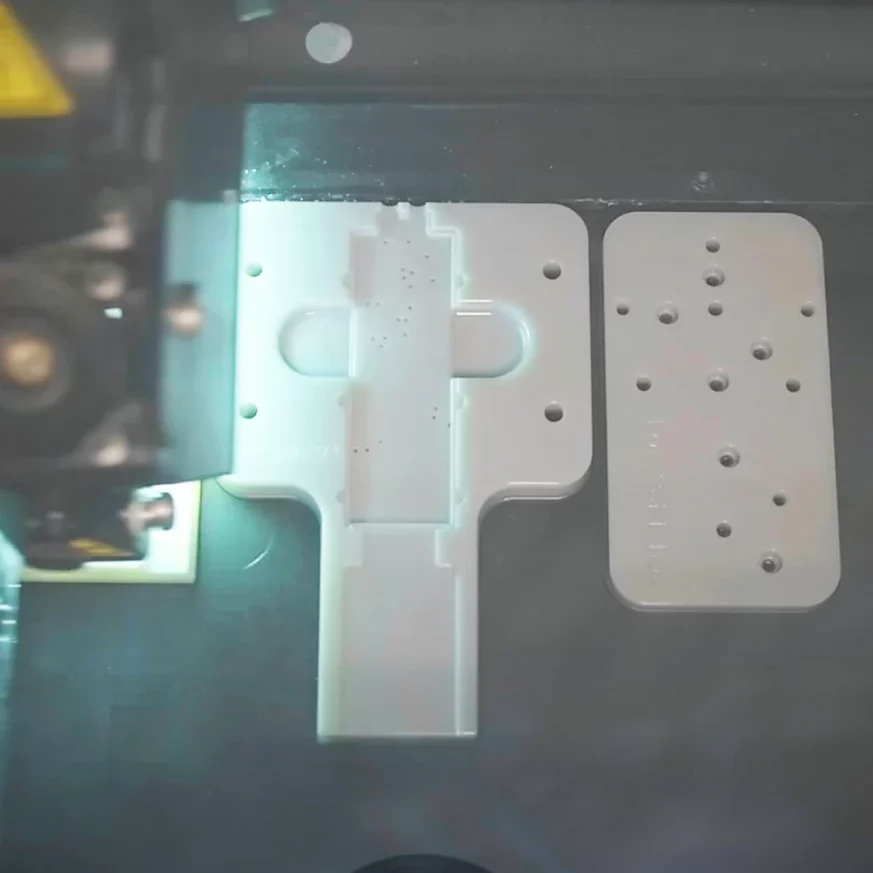

3D prototyping is mainly used to check feasibility

Altyor’s mechanical engineering design office is one of the very first design offices to buy 3D printers in France. Our in-house prototyping strategy offers Altyor’s customers complete confidentiality over their projects. Our equipment also enables us to be more reactive in design without having to resort to expensive tooling.

The engineers and technicians in Altyor’s mechanical engineering department are always on the lookout for new developments in 3D printing, and keep a close watch on the latest technological developments, so as to meet our customers’ expectations as effectively as possible.

However, some complex products require the use of molds to validate essential product components such as watertightness and strength.

To achieve this, we’ve built up a network of qualified partners so that you can benefit from the latest innovations for an optimal prototyping phase.

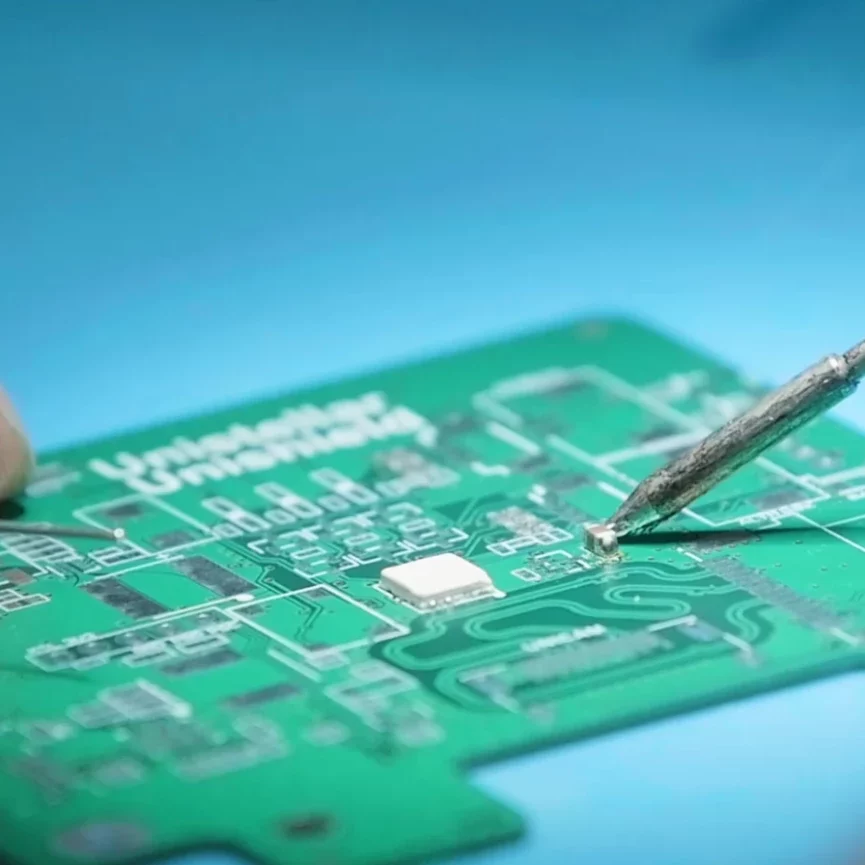

Two-step electronic prototyping

On the electronics side, Altyor’s electronics design office is carrying out two prototyping stages. The aim of the first PCB prototype is to carry out software development as early as possible, to carry out an initial assessment of the certification protocol and to present our customer with a demonstrator.

The second prototype will enable us to take into account all the comments made on the certification protocol, make modifications following the start-up of the 1st prototype, produce the manufacturing file for the pre-production run, and validate the on-board software. It will also validate all the functionalities defined in the specifications.

Our programs to suit your needs

UnLock program

Need help defining the specifications for your connected product?

LaunchPad program

Do you need to design and produce

functional prototypes?

ScaleUp program

Do you need to design and manufacture

your connected object?

Infinity program

Want to give your product a second life

your product through a circular economy loop?