Recycled plastic (RPM) is now establishing itself as a credible industrial solution for companies developing hardware products. Long confined to secondary uses, it now meets high standards in terms of performance, quality, and sustainability.

For start-ups, SMEs, and manufacturers committed to eco-design, the challenge is no longer whether to use recycled plastic, but how to effectively integrate it into a product intended for industrialization.

Key points at a glance

Recycled plastic can achieve performance levels comparable to virgin materials.

It significantly reduces the carbon footprint of the material.

Its integration must be considered from the design stage onwards.

A controlled industrial approach is essential to guarantee quality and repeatability.

“In 2024, I saw the commitment and passion of the Altyor teams to designing products that are as innovative as ever, to industrializing products that are as high-performance as ever […] All this with strong eco-design reflexes and a greater understanding of the impact of our company and the products we design.”

Yanis Cottard, President of Altyor

Why recycled plastic is becoming standard in hardware

A concrete response to regulatory and societal challenges

European regulatory requirements are changing rapidly. Extended producer responsibility with bonuses for integrating MPR, environmental transparency obligations, increased consumer expectations, current French regulations (AGEC Law) and upcoming European regulations (ESPR): the context is pushing companies to rethink their choice of materials.

In this context, recycled plastic is a concrete, measurable, and credible response to sustainability challenges.

Increasingly structuring market expectations

Expectations no longer come solely from public authorities. End customers, distributors, investors, and industrial partners are now paying close attention to how products are designed and manufactured.

In many calls for tenders, the consideration of environmental criteria is becoming a differentiating factor. The integration of recycled plastic makes it possible to meet these requirements without compromising product performance. It helps to build a more responsible brand image, while remaining credible from an industrial standpoint.

Securing supplies and strengthening industrial resilience

Beyond environmental issues, recycled plastic also addresses a very practical problem: securing supply chains.

Pressure on virgin raw materials, price volatility, and geographical dependencies are undermining traditional industrial models. By relying on structured recycling channels, which are often more local, companies are becoming more resilient and predictable.

Recycled plastic thus becomes a strategic lever, not only for reducing carbon footprint, but also for limiting industrial risks related to supply.

Recycled plastic and industrial performance: challenging preconceived notions

By 2025, 83% of the plastic used at Altyor will come from 100% recycled materials. And guess what? These products are just as attractive, just as effective, and sometimes even cheaper than their virgin material equivalents.

Mechanical strength and durability of parts

A common misconception persists: recycled materials are less reliable.

In reality, properly selected, qualified, and processed recycled plastic can offer mechanical performance compatible with demanding hardware products.

Premium aesthetics and finishes

Contrary to popular belief, recycled plastic does not mean sacrificing aesthetics.

Textures, colors, surface finishes: many finishes are now available, using the right sources of materials.

Material stability and repeatability in production

The real issue is not recycled plastic itself, but its consistency over time.

A controlled industrial process ensures stable production, which is essential for reliable mass production.

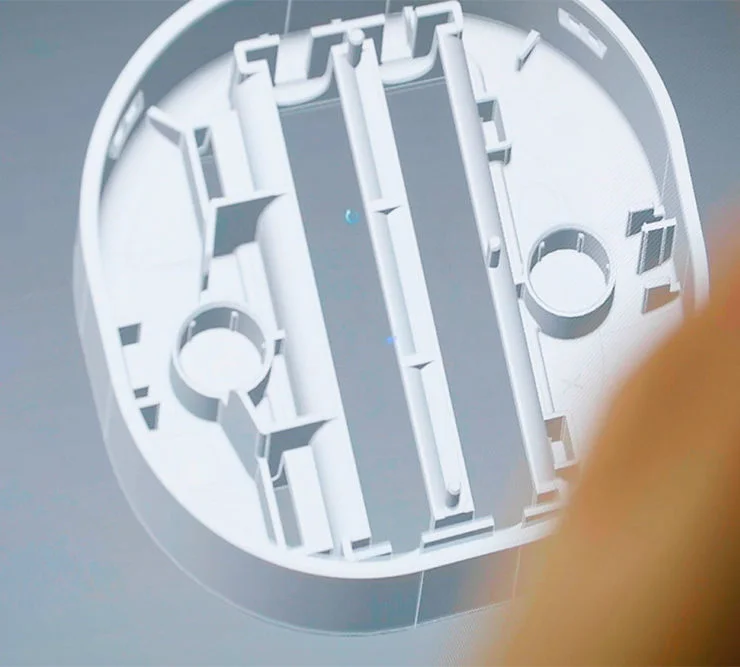

Should the design be modified to use recycled plastic?

This is one of the first questions asked by companies wishing to incorporate recycled plastic into their hardware products.

The answer is reassuring: in most cases, a complete redesign of the product is not necessary.

Molds, processes, and materials: proven compatibility

Recycled plastic is equivalent to thermoplastic and can be integrated without any disruption to industrial processes.

Its mechanical properties and injection behavior are very similar to those of virgin material.

Result:

✅ The molds remain compatible

✅ The processes remain unchanged

✅ Production rates are maintained

This allows companies to introduce recycled plastic without starting from scratch.

Possible design adjustments to ensure performance

During the design or optimization phase, certain adjustments may be recommended to ensure product performance:

- reinforce areas subject to mechanical stress with ribs,

- adjust thicknesses locally.

These changes remain marginal. They are more a matter of industrial optimization than product redesign.

During the testing and validation phases, it is also possible to mix virgin material with recycled plastic.

Which plastics can be recycled?

At Altyor, we work with a comprehensive range of recycled technical materials:

🔹 Recycled ABS: Impact resistance and rigidity, perfect for industry, automotive, and electronics

🔹 Recycled MABS: Transparency and mechanical strength for premium-looking parts

🔹 Recycled PC (Polycarbonate): Exceptional transparency and superior mechanical strength

🔹 Other engineering polymers: We tailor our solutions to your specific needs

From material to product: structuring an industrial recycling loop

Going beyond the occasional use of recycled materials

Using recycled plastic in a product is not enough to guarantee a truly sustainable approach. The challenge lies in the ability to structure a coherent recycling loop, designed at the level of the product and its life cycle.

Without clear industrial organization, there is a risk of multiplying heterogeneous batches, with variations in quality that are difficult to control. Conversely, a structured approach ensures consistent performance, which is essential for reliable mass production.

Traceability, extrusion, and quality control

The performance of recycled plastic depends directly on the steps that precede its injection.

Sorting, grinding, extrusion, quality control: each phase influences the final mechanical and aesthetic properties.

A controlled industrial process enables:

- ensure the traceability of materials,

- stabilize formulations,

- to ensure repeatability compatible with industrial requirements.

This expertise is essential for moving from experimental use of recycled materials to sustainable industrialization capable of handling large volumes without compromising on quality.

👉 This logic is fully in line with a circular economy approach, where the product is seen as a future resource rather than waste.

How can I guarantee the technical quality of my products made from recycled materials?

Quality is our obsession at Altyor. Here’s how we guarantee it:

✔️ Quality control at every stage: From recovery to injection, every decision counts

✔️ Performance testing: Mechanical resistance, thermal stability, accelerated aging

✔️ Full traceability: Precise knowledge of the origin of the material

✔️ Certification and compliance: Compliance with REACH, RoHS, and WEEE standards

📈 Result: Products that retain 100% of their technical properties!

“Every decision in plastic recycling is crucial. Incorrect sorting can cause black spots on the re-injected product, while poor homogenization can lead to a loss of technical performance.”

The Design for Tomorrow team, Altyor

Open loop or closed loop: structural choices

Two major approaches coexist in the industry:

- The open loop, where recycled material comes from external sources (industrial or post-consumer waste).

- The closed loop, which involves recovering end-of-life products, dismantling them, and reintegrating their materials into the production cycle.

The closed loop offers a higher level of control over the quality of recycled plastic. However, it requires careful consideration of product design at an early stage: ease of disassembly, ease of sorting materials, limiting mixtures.

👉 Discover our circular economy models

Closed loop: a demanding model, reserved for high-volume projects

The closed loop represents the most advanced stage of a circular economy approach. It involves recovering end-of-life products, dismantling them, and then reintegrating their recycled plastic into a new production cycle.

A model suited to significant volumes

Setting up a closed loop involves:

- collection logistics,

- sorting and dismantling operations,

- dedicated extrusion and quality control.

These steps require sufficient volumes to be economically viable. This is why closed-loop recycling is mainly aimed at products that are already industrialized, with large production runs and long-term visibility.

Eco-design as a prerequisite

Even if closed-loop recycling is not immediately implemented, it is essential to lay the groundwork during the design phase. Certain choices greatly facilitate future recycling:

✅ Avoid dual-material products (e.g., ABS + silicone glued together)

✅ Ban labels glued directly onto plastic

✅ Remove ultrasonic welds that make dismantling impossible

✅ Favor clip-on systems to facilitate disassembly

✅ Replace paint with pad printing

💡 Expert tip: The easier your product is to disassemble, the cleaner and higher quality the recycled material will be. Even if a closed loop is only a long-term goal, these design choices are always beneficial.

How can you successfully eco-design your electronic product?

Eco-design brings together all the levers for reducing a product’s environmental footprint, whether in terms of power consumption, durability, packaging or other factors. In this guide, our experts have put together 15 key points to show you the actions you can take to act effectively.

What is the real environmental impact of recycled plastic?

Life Cycle Assessment (LCA) remains the benchmark tool for objectively assessing environmental gains.

It allows for a precise comparison between virgin material and recycled plastic throughout the entire product life cycle.

🏭 Significant savings in fossil raw materials

♻️ Reduction in plastic waste and reintegration into the production cycle

💚 50% reduction in carbon footprint for a plastic part made from recycled material compared to virgin material

By 2024, Altyor had reduced its carbon footprint by 41%, mainly through the increased use of recycled plastic (87% recycled plastic in 2024). This is our concrete commitment to ecological transition.

‘Using recycled plastic significantly reduces our environmental footprint. For our injection-moulded parts, we have measured a 50% reduction in our carbon footprint simply by changing the material. That’s huge.’

Design for Tomorrow Team, Altyor

Take Action: Altyor Tools at Your Disposal

Our 100% French supply chain since 2020

For over 10 years, we have been developing our recycling loop, and since 2020, our supply chain has been exclusively French. We have built up a network of expert partners at every stage:

🏭 Specialised injection partners

♻️ Recycling and regeneration experts

🔬 Quality control laboratories

🚚 Optimised recovery logistics

Design for Tomorrow: Our expertise unit

Our team dedicated to sustainable development supports you in:

📊 Conducting comprehensive LCA assessments

🎨 Eco-designing your products

🔄 Setting up recycling loops

📈 Calculating the Design for Tomorrow index

🎓 Training your teams

Our catalogue of recycled materials

We offer a comprehensive range of high-performance recycled materials, ready to be injected into your products. All our materials are certified, traceable, and available in several colours.

👉 Need information or want to place an order?

🌟 They did it with Altyor, why not you?

Free has incorporated our recycled material into its Freebox Révolution

Bob uses our recycled plastic for its mini dishwasher

In 2020, 34% of the plastic used by Altyor was recycled.

By 2025, this figure had risen to 83%.

And this is just the beginning!

Get a quote tailored to your project!

FAQ — Recycled plastic & hardware products

What is recycled plastic?

Recycled plastic is produced from the recycling of industrial or post-consumer plastic waste. After sorting, grinding and extrusion, it is reprocessed into granules that can be used in plastic injection moulding to manufacture new parts, including hardware products.

Can we achieve a quality equivalent to that of virgin material?

In many cases, yes. Advances in recycling processes now make it possible to achieve a controlled level of quality, with finishes suitable for consumer or premium products.

Is recycled plastic more expensive?

The good news: If done right, a recycling loop can be economically neutral or even profitable!

💰 Costs to consider:

– Setting up collection logistics

– Partnerships with specialised recycling companies

– Possible design adjustments

Our French division has been in existence since 2020 and is built around expert partners. We can support you every step of the way!

What is the difference between open-loop and closed-loop recycling?

An open loop uses recycled materials from external sources.

A closed loop involves recovering end-of-life products to reuse their materials in new products. The closed loop offers better control over quality and traceability, but requires appropriate design from the outset.

Why seek assistance when incorporating recycled plastic?

Because incorporating recycled plastic involves technical, industrial and economic trade-offs. An experienced partner helps to secure design choices, qualify materials and ensure consistent industrialisation without compromising quality or deadlines.