Life cycle assessment (LCA)

Quantify impacts and make decisions

Life Cycle Assessment (LCA) is carried out by our Design for Tomorrow department and is included in the eco-design justification file, which aims to assess the eco-responsibility of a product throughout its development.

What are the advantages of LCA?

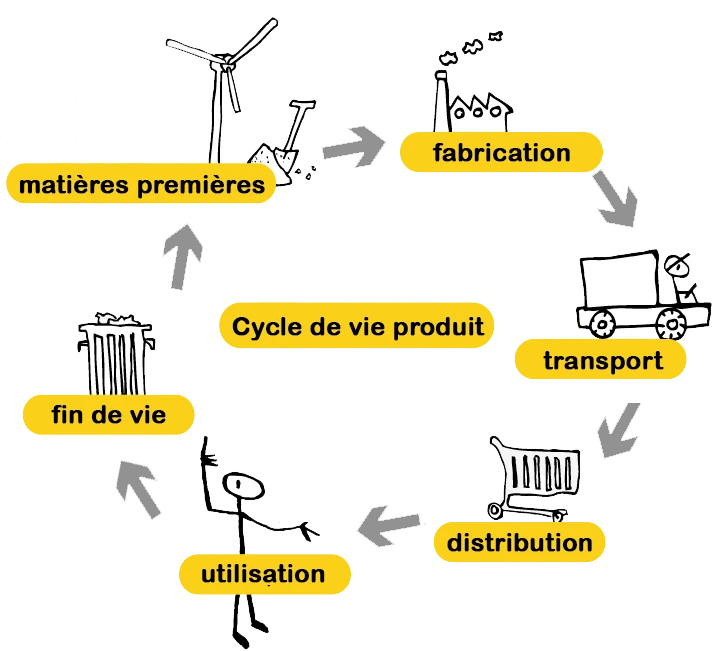

More specifically, LCA aims to quantify and identify all the material and energy flows involved in the life cycle of a product, service or process, through :

Why conduct a life cycle assessment?

Lifecycle analysis is the 1st step in implementing an informed and relevant eco-design approach, by quantifying and assessing the impact of a product’s entire lifecycle. It makes it possible to compare choices on a global scale (recycling, relocation of production) or a local scale (design element, manufacturing process). Finally, LCA targets the best levers for reducing overall impact.

Can we help you with your project?

What are the stages in a life cycle assessment?

Life cycle assessment is an iterative process, with each phase of an LCA using the results of previous phases, and going back and forth each time.

Life cycle assessment is carried out in 5 stages, starting with the definition of the objectives and scope of the study, followed by the inventory. The inventory includes the identification and quantification of element such as manufacturing processes (including the disposal of process and product waste), the production and consumption of fuels, electricity and heat, lighting and heating, distribution and packaging, and the recovery of products after use (reuse, recycling and energy recovery). The 3rd stage of LCA is the evaluation of environmental impacts, leading to the 4th stage, which is the analysis of the evaluation results.

At the end of the process, LCA enables us to understand the relevant areas for action, so that we can take effective action.

The key stage of an LCA: Stage 5, Taking action

The 5th step is a result of the life cycle analysis carried out. In the light of the findings, actions can be taken that will have an impact:

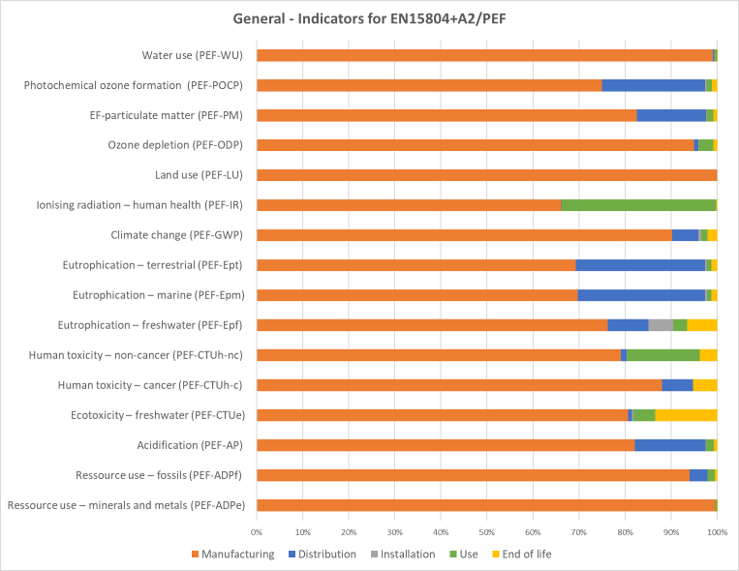

Example of a life cycle analysis

Opposite is an extract from the lifecycle analysis of a connected button. This graph enables us to identify which phase of the lifecycle has the greatest impact. The production phase, shown in orange on the graph, is the most costly in terms of the product’s environmental footprint.

FAQs on life cycle assessment

How do you perform a life cycle assessment (LCA)?

We can help you calculate and analyze your product’s ecological footprint using LCA.

Life cycle assessment is the starting point for understanding your product’s impact on the environment. To help you understand the ins and outs of LCA (Life Cycle Assessment), we’ve put together 14 answers that will shed some light on the subject.