When a company develops a hardware product, the question of “who will manufacture it” arises very quickly. Often, the search is conducted from the perspective of outsourcing: identifying a factory, comparing quotes, and launching production.

But this approach quickly reaches its limits.

Subcontractor or industrial partner: a key difference

A subcontractor carries out a set of specifications.

An industrial partner commits to the overall success of the project.

They are involved from the earliest stages, challenging technical choices, anticipating industrial constraints, and supporting the product throughout its life cycle. As products become more complex and connected, and requirements increase, choosing the right industrial partner becomes a major strategic issue.

Pourquoi le choix du partenaire industriel est décisif en hardware

Hardware imposes specific constraints: initial investments, unavoidable delays, certifications, dependence on the supply chain. Unlike software, an industrial error cannot be corrected with a simple update.

Choosing the wrong industrial partner can result in:

- delays in bringing products to market,

- an explosion in costs during the industrialization phase,

- quality or compliance issues,

- an inability to move from prototype to mass production.

Conversely, an experienced industrial partner allows you to consider the industrialization of the product from the design stage (DFM), anticipate risks, and transform an innovation into a reliable, industrializable, and scalable product.

The essential criteria for choosing the right industrial partner

Price is only one indicator

In a hardware project, the real challenge lies in the overall cost of the project, not just the unit price.

Highly attractive offers can mask weaknesses, while high costs are not necessarily synonymous with quality. Transportation, customs, import constraints, delays, poor quality, returns, inventory immobilization, and crisis management are all hidden costs that can quickly cancel out apparent savings.

A relevant industrial partner thinks in terms of total cost of ownership and supports you in balancing price, quality, and reliability, with a long-term vision.

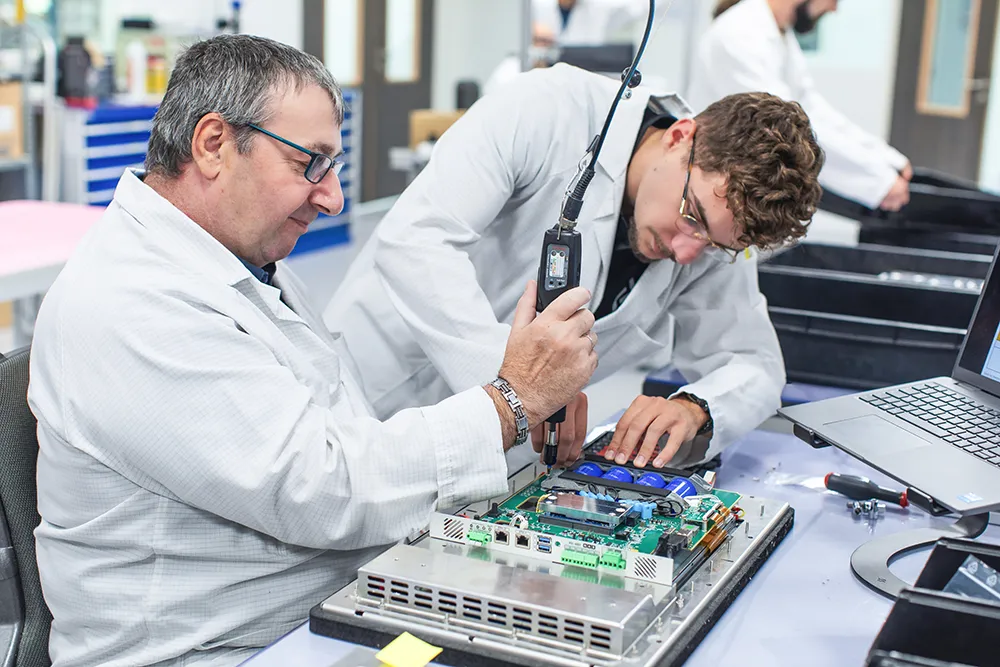

Technical expertise and sectoral legitimacy

The success of innovative or complex products depends on a partner who combines technical expertise with industry experience.

It is essential to check:

- les produits déjà industrialisés,

- experience in your sector of activity (IoT, Fintech, industry, MedTech, EdTech, Smart Home, etc.),

- the ability to manage complex assemblies,

- the existence of testing, validation, and quality control measures.

Customer references and case studies are often the best indicator of this legitimacy.

Lead times, responsiveness, and production strategy

In a hardware project, deadlines do not depend solely on a theoretical schedule.

They are directly linked to the production strategy put in place and the industrial partner’s ability to orchestrate the entire chain.

A reliable industrial partner must be able to:

- propose realistic schedules, aligned with the maturity of the product,

- respond quickly in the event of unforeseen circumstances (supplier delays, technical adjustments, volume variations),

- Ensure production continuity, even in uncertain times.

The location of production sites plays a key role here.

Local production can offer greater proximity, flexibility, and speed of iteration. Conversely, more distant production may be appropriate for certain volumes, provided it is perfectly managed.

👉 The challenge is therefore not to choose between France and the international market, but to define a coherent industrial strategy that combines:

- responsiveness during the development phase,

- reliability during production,

- control of costs and deadlines over time.

Supporting ramp-up, from prototype to mass production

Moving from a working prototype to reliable mass production is one of the most critical stages of a hardware project.

An industrial partner must be able to provide support:

- the prototyping phases,

- pre-production runs to validate processes,

- the gradual increase in volumes,

- full industrialization for the series.

This ramp-up involves adapting production lines, securing supplies, and implementing robust quality controls.

👉 Discover the different steps involved in moving from prototype to mass production.

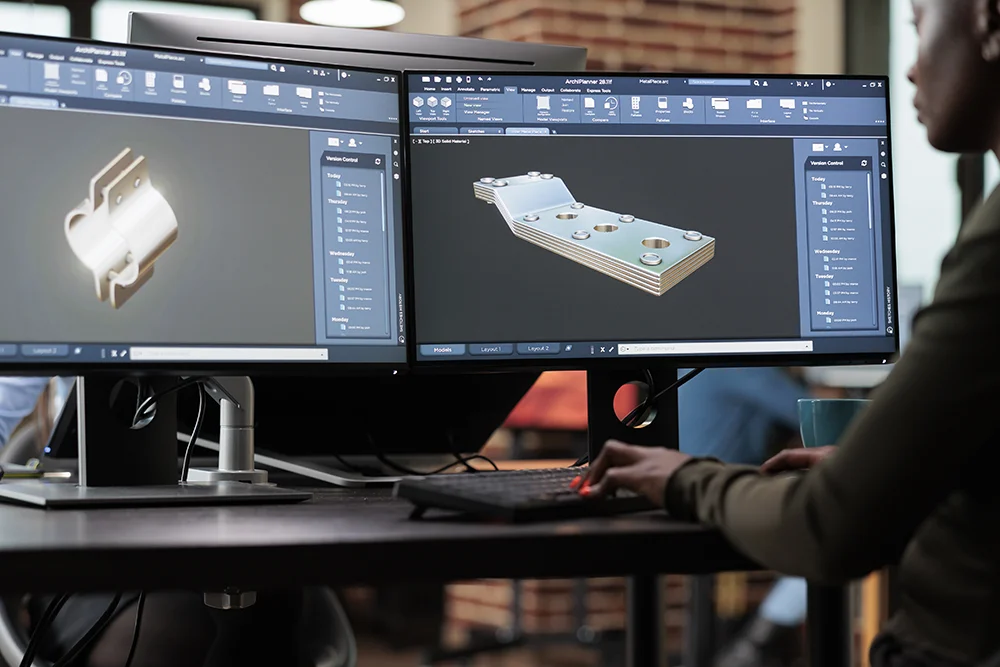

Integrate DFM from the design stage

A product designed by an engineering firm is not necessarily a product that can be immediately industrialized.

This is precisely the role of the Design for Manufacturing (DFM) approach.

A competent industrial partner must be able to analyze the product design from the earliest stages in order to:

- identify and resolve bottlenecks in manufacturing,

- to simplify assemblies,

- to optimize production costs,

- to ensure consistent quality in series production.

Without DFM, problems often arise too late, at the tooling or pre-production stage.

Support that goes beyond production

Producing an object is only part of the challenge.

The real challenge is producing the right object, on time, at the right cost.

A committed industrial partner can assist with:

- mechanical and electronic design,

- optimization for industrialization,

- support for certification,

- the structuring of after-sales service,

- product developments.

This comprehensive approach reduces friction, back-and-forth communication, and additional costs.

Financial strength and long-term vision

Hardware products evolve over time. Your industrial partner must therefore be able to commit to the long term, invest, and support growth in volumes.

Financial strength is an often overlooked criterion, but one that is crucial in avoiding industrial disruptions.

Altyor, an industrial partner designed for ambitious projects

At Altyor, our approach is based on a simple principle: design to produce, and produce to last.

This translates to:

- comprehensive support from design to production,

- a mastery of mechanics and electronics,

- a France/China production strategy tailored to the challenges of each project,

- strong integration of eco-design,

- Concrete references in more than 10 sectors (Fintech, MedTech, Energy, Smart Home, Robotics, LeisureTech, EdTech, Mobility, Industry, etc.)

Industrial manufacturer for

over 25 years

+ More than 700,000 products/year

including 150,000 in France

Responsible manufacturing

Are you ready to partner with an industrial partner?

Engaging with an industrial partner is not a simple administrative step.

It is a turning point in the life of a hardware project.

At this stage, the question is no longer simply “can we manufacture this product?”, but “are we ready to produce it under the right conditions?”

The maturity of the specifications is a key initial indicator. When sufficiently structured, they enable manufacturers to understand uses, anticipate technical constraints, and propose optimizations. Conversely, vague or overly rigid specifications can mask risks that will only become apparent during the industrialization phase.

This consideration must also take into account the targeted volumes, ramp-up, and regulatory constraints. A viable pre-production project can become fragile in series production, especially if these issues are addressed too late.

Finally, it is essential to verify that the product has been designed for industrialization, and not just to demonstrate a concept. A functional prototype is not necessarily industrializable as is.

👉 If these issues still raise doubts, it is often the right time to seek support.

Get a quote tailored to your project!

Choosing an industrial partner is not the same as selecting a supplier.

It means embarking on an industrial journey, with all its risks, opportunities, and ambitions.

The right partner is one who secures your project, challenges your choices, and helps you scale up sustainably.

👉 Discover Altyor’s Unlock, ScaleUp, and Infinity programs to support your project at the right level of maturity.

Our programs to suit your needs

UnLock program

Need help defining the specifications for your connected product?

LaunchPad program

Do you need to design and produce

functional prototypes?

ScaleUp program

Do you need to design and manufacture

your connected object?

Infinity program

Want to give your product a second life

your product through a circular economy loop?