When it comes to your company’s ecological footprint and environmental impact, the first key step is product life cycle analysis. This tool enables you to quantify the environmental impact of your manufacturing processes and choices. This method provides you with concrete points for improvement, enabling you to adopt an eco-design approach.

What is LCA?

LCA, or Life Cycle Assessment, is a scientifically approved method. It is used to assess the environmental impact of products or services throughout the manufacturing process.

It is governed by a set of international regulations that delimit its field of action and determine the indicators to be measured. ISO standards 14044 and 14040, dedicated to corporate environmental management and performance, provide a framework for this analysis method. They provide details on how to conduct the study to verify product eco-design.

If you are a manufacturer, we strongly advise you to carry out an LCA for each of the goods or services you offer.

➡️ You can ask an independent organization to read your conclusions. You’ll gain credibility and build a solid case to fall back on.

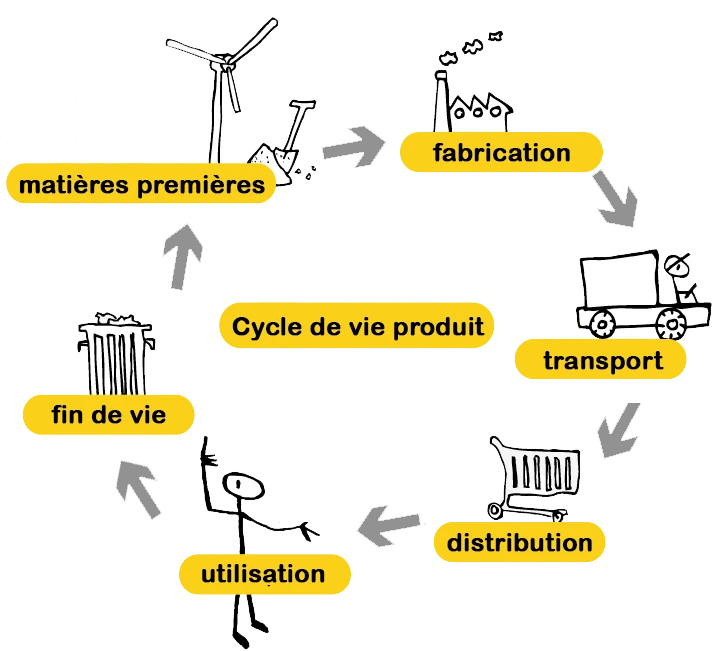

LCA, at the heart of the different phases of a product’s life cycle

This standardized method covers the entire life cycle of a product:

- Raw materials: procurement and transport.

- Manufacturing processes: molding, part assembly, packaging.

- Circulation: distribution and marketing.

- Product use: energy and maintenance costs.

- End-of-life: reuse and waste treatment.

L’analyse du cycle de vie vous aide et oriente :

In the end, you’ll have access to concrete avenues for improvement tailored to your organization. LCA remains a powerful lever you can use to reduce your environmental impact.

By analyzing the development stages of your products, you can adopt a strong eco-responsible approach. You take action on the way you produce, and reduce your waste.

Why analyze a product’s life cycle?

The main aim of LCA is to identify all the elements involved in the life cycle of a product, service or process.

Each resource used is studied, analyzed and listed. For each flow identified, environmental factors are associated.

This approach is also multi-criteria, taking into account :

The success of this study depends on a solid database and appropriate tools. You can train your own teams or call on the services of an outside organization.

➡️ We carry out the LCA of your product within our sustainable development unit.

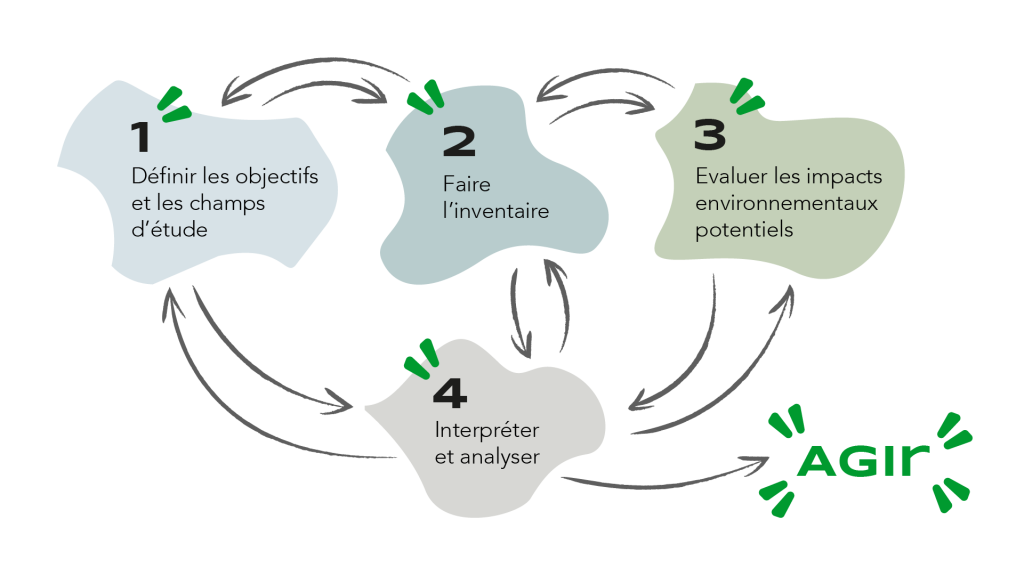

How to carry out a product life cycle analysis?

LCA is not a linear method. It is based on the results obtained as each stage is completed. This means that there is a lot of back-and-forth throughout the study.

Step 1: Define study objectives and scope

To begin an LCA, you need to define the objectives of the analysis and determine its scope. You list the stages of the product’s life cycle concerned by the study. But also how you will present the results.

Step 2: Draw up a Life Cycle Inventory (LCI)

You list all incoming and outgoing flows involved in the product life cycle:

➡️ To avoid making mistakes, use dedicated software or a spreadsheet.

Step 3: Assess potential environmental impacts

Each incoming or outgoing flow identified in step 2 is associated with two categories of environmental impact: midpoints and endpoints.

The midpoints identify the problematic factors linked to LCI results. Endpoints refer to potential long-term damage.

Step 4: Interpret and analyze results

You interpret the results obtained, according to the objectives set before the LCA. Corrective measures become apparent. You can then implement measures that will have an impact:

- Eco-design a product with our mechanical and electronic engineering department.

- Use recycled raw materials.

- Rethink product end-of-life with Altyor’s Refurbishing/Recycling loops.

How do you perform a life cycle assessment (LCA)?

We can help you calculate and analyze your product’s ecological footprint using LCA.

Life cycle assessment is the starting point for understanding your product’s impact on the environment. To help you understand the ins and outs of LCA (Life Cycle Assessment), we’ve put together 14 answers that will shed some light on the subject.

When should you carry out a Life Cycle Assessment?

The RE 2020 environmental regulation concerns new buildings in particular. It makes LCA mandatory before work begins.

If you’re not subject to this standard, you can still carry it out before launching a new product. It will help you with the design and guide your choices in terms of :

So you can measure impacts even before the product is marketed, and limit your environmental footprint. More than just a tool, LCA is a powerful ally in project development.

Finally, product lifecycle analysis can be used to redefine your strategy, review your production methods or improve your processes. You’ll gain valuable insights that will enable you to take the corrective action best suited to your production model.

What are the limits of LCA?

This method has its limitations. These are concentrated around 2 main themes: study set-up and environmental factors.

You may find it difficult to carry out an LCA:

Today, some environmental factors cannot be studied. These include :

Product lifecycle analysis remains a powerful tool available to companies for assessing and quantifying their environmental impact. Although this standardized and approved method covers a large number of factors, it does have certain limitations, beyond the control of company managers.

LCA is part of your CSR policy. In the podcast below, we take a look at building a positive impact business model.

Get a quote tailored to your project!

From design to industrialization, production and remanufacturing, we offer ongoing, customized global support to ensure the success of your project.

01

Innovation support

_Building a solid foundation for your industrial project

02

Mechanical and electronic design

_Giving lasting life to your product

03

Industrialization

_Industrializing your product to make your production more reliable

04

Production

_Implementing your robust production line

05

Remanufacturing

_Supporting your product’s life cycle