Moving from a working prototype to reliable mass production is a decisive step for any hardware project.

Between quality requirements, cost control and tight deadlines, choosing the right manufacturing location and industrial manufacturer becomes a strategic decision.

Today, manufacturing hardware in France is attracting more and more innovative companies.

Proximity, responsiveness, traceability: these are just some of the advantages that are restoring Made in France manufacturing to a central place in electronics and IoT projects.

This was the message conveyed by Altyor and FillnDrive during the SIDO 2025 conference:

‘Why choose France to manufacture hardware in an innovative sector such as hydrogen?’

Why manufacture hardware in France?

Local production is primarily a question of industrial expertise.

Companies that develop hardware must be able to quickly adjust, test and improve their products before moving into mass production.

Proximity and responsiveness

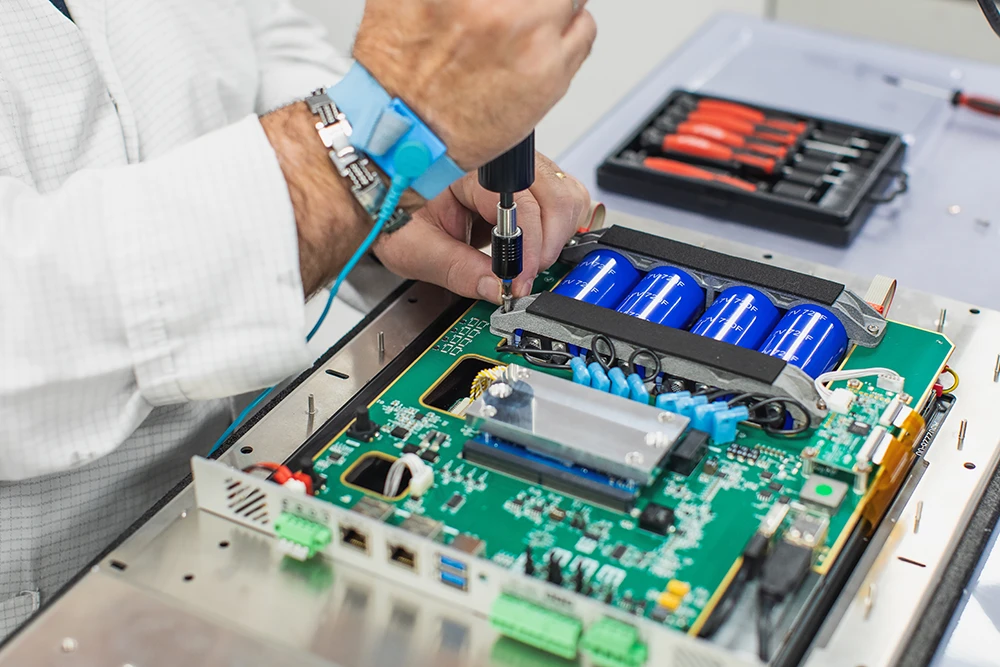

Mass production in France allows for direct communication between the customer, engineers and technicians.

At Altyor, adjustments can be made in less than 24 hours thanks to the proximity between our design offices and our assembly workshop in Orléans.

This responsiveness, which is essential in the pre-production phases, ensures a shorter time-to-market and reduces the risk of non-compliance.

Agility and flexibility

Contrary to popular belief, French sites are highly adaptable.

Altyor lines can switch from small-scale to medium-scale production in a matter of days, without heavy investment.

This agility is reinforced by the presence of mechanical and electronic design offices on the same site, enabling continuous product design optimization.

“For small production runs, France is often more flexible than China.”

The Altyor approach: from design to mass production

Altyor masters the entire industrial chain:

from mechanical and electronic design to mass production of hardware, including industrialization and DFM (Design for Manufacturing).

Altyor has two complementary sites to ensure production:

- Orléans (France): local production, greater flexibility and customer proximity.

- Shanghai (China): high-volume production and international competitiveness.

Get a quote tailored to your project!

Case study: Altyor x FillnDrive

Designed to meet the specific needs of hydrogen filling stations, FillnDrive offers simplified management via an intuitive interface and solutions that comply with legal metrology requirements. The company offers a touchscreen for end users, facilitating hydrogen refuelling and driving.

To transition from artisanal manufacturing to mass production, the company chose Altyor as its industrial manufacturer.

The project was carried out in three key stages:

- DFM optimisation to simplify assembly and improve manufacturing reliability.

- Industrialization in Orléans, in direct collaboration with FillnDrive engineers.

- Small-batch production within a few months, with comprehensive quality control.

The results obtained:

- Labour costs divided by 2.6

- Reduced time to market

- Full traceability

- Industrialised process

- Rapid skill development of the customer team

“Nous sommes passés d’un ‘We have transitioned from a handcrafted product to an industrial product without losing our agility.’artisanal à un produit industriel, sans perdre notre agilité.”

Merwan Akasbi, FillnDrive

How to manufacture a hardware product on a large scale?

Going from prototype to production is a critical turning point. Wrong choice of partner, quality defects, delays… a mistake can be costly.

This guide, designed by Altyor’s experts, will help you structure your approach and avoid the pitfalls. You will find clear advice on how to manage your production with peace of mind.

A comprehensive industrial model: agility, sustainability and performance

Altyor’s expertise extends beyond production.

It offers a complete service covering the entire product life cycle:

- Integrated design office (mechanical and electronic)

- Industrialization to ensure reliability at every stage of mass production

- Controlled supply chain, with traceability and responsible sourcing

- LCA and eco-design to reduce environmental impact

This organisation reduces hidden costs, speeds up time to market and ensures quality over time.

Manufacturing in France: a strategic and sustainable choice

Choosing mass production in France means focusing on proximity, reliability and sustainability.

For innovative start-ups and SMEs, this choice offers a clear competitive advantage:

- Greater responsiveness

- Greater flexibility

- Controlled production from prototype to mass production

Altyor positions itself as the French industrial partner for companies that want to design and manufacture their hardware in France, with high technical and environmental standards.

Are you looking to industrialize your hardware product? Contact the experts at Altyor to launch your mass production.