Plastic injection molding is currently one of the most widely used processes for manufacturing these parts, as it allows for the production of complex shapes that are reproducible and suitable for a wide range of uses. However, in order to achieve reliable, aesthetically pleasing, and industrially optimized results, several best practices must be mastered: conception, material selection, mold design, process adjustment, validation, etc.

At Altyor, we have been working for over 30 years on injection-molded parts for consumer electronics, IoT, and industrial products. Thanks to this experience, we have identified the key factors that enable us to produce robust plastic parts with a high-quality finish that meet the product’s requirements.

This article brings together the essential best practices to know when designing and producing parts using plastic injection molding.

Plastic injection molding: an essential process

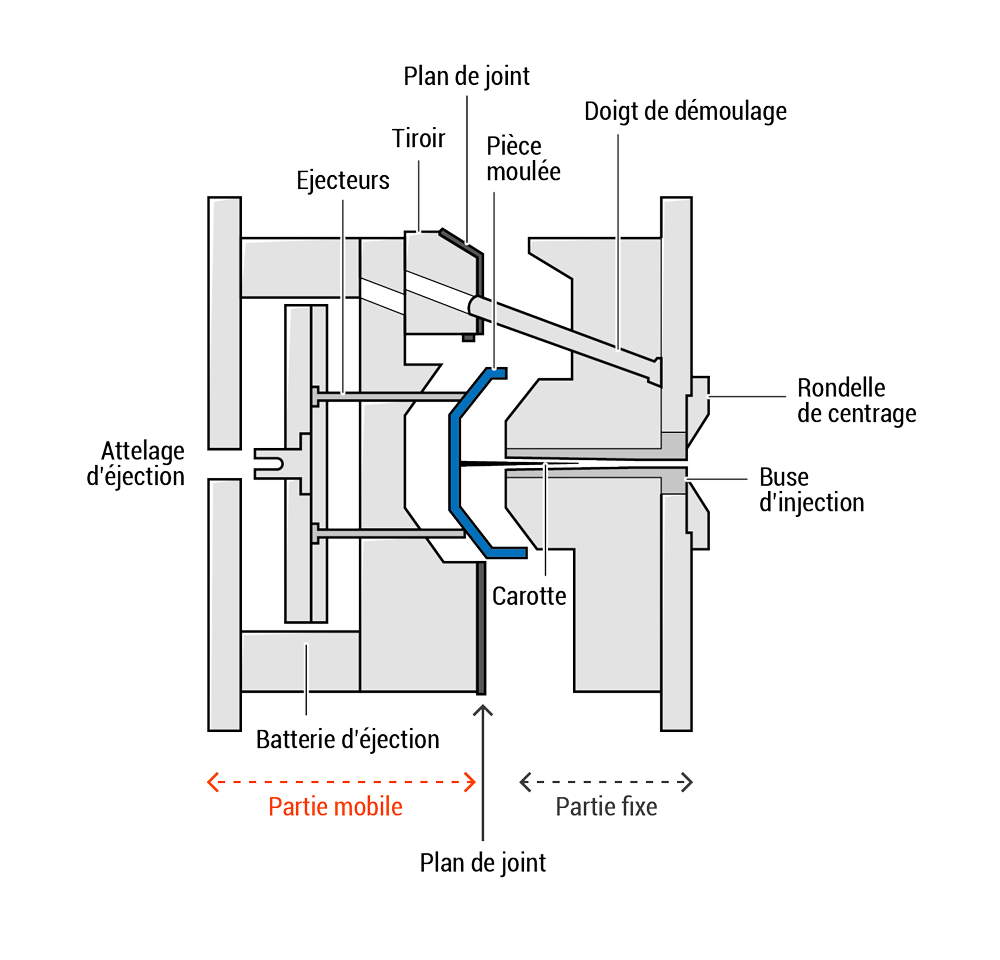

Plastic injection involves heating a thermoplastic polymer, liquefying it, and then forcing it under high pressure into a metal mold. Once cooled, the material takes its final shape and forms the part.

This process dominates the hardware world because it offers decisive advantages:

- the ability to produce complex shapes

- a competitive unit cost in series production

- excellent repeatability

- high mechanical performance

- a wide selection of materials suitable for all uses

👉 For the basics: Plastic injection molding: definition & benefits

Choosing the right material: the foundation of performance

The choice of material, virgin or recycled, is one of the decisions that determine the final quality of the part. It is also a trade-off between mechanics, aesthetics, and environmental impact.

How to choose the right material for your product?

Each polymer has its own characteristics. The right material is one that meets the mechanical, thermal, and aesthetic requirements of the product.

ABS remains the classic choice: an affordable, stable thermoplastic that is easy to inject and offers a beautiful surface finish. It is particularly well suited to electronic enclosures and everyday products.

Polycarbonate (PC) is chosen for its extreme impact resistance. When a product needs to survive a fall or repeated stress, it is often the ideal material.

Polyamide (PA) is suitable for technical products subject to high mechanical or chemical stresses. It is often used in the automotive industry or in more demanding environments. It is ideal for structural parts.

The choice is never insignificant. It responds to usage constraints that the manufacturer must analyze from the outset of the project.

Incorporating recycled plastic: a sensible and responsible choice

Recycled plastic is a serious, effective, and often underestimated option.

Colors, strength, material consistency: many still think it is unstable. This is not true.

Don’t be afraid to use recycled materials. Some suppliers, such as Altyor, offer high-quality materials that deliver the same aesthetic performance as virgin materials.

When used correctly, it can significantly reduce environmental impact without compromising performance.

Designing a part optimized for injection molding

Constant thicknesses and draft angles: the absolute rules

A plastic part must not have excessive variations in thickness.

Why? Because the material cools and contracts differently depending on the area.

Result: defects, deformations, surface marks.

The draft angles facilitate the ejection of the mold. Without sufficient draft angles, the part may get stuck, be marked, or damage the mold.

Reinforcements, ribs, and clips: smart stiffening

The typical beginner’s mistake? Thickening the walls to stiffen the piece.

The solution? Add ribs.

They offer:

- increased rigidity,

- a reduction in material consumption,

- better stability.

Clips must be designed to withstand repeated assembly and disassembly cycles. This is a delicate art, where the choice of material has a significant impact on the design.

Anticipating defects from the design phase onwards

Every decision must take into account how the material will behave in the mold.

The goal: to avoid visible or structural defects.

A well-designed part must anticipate:

- shrinkages

- injection marks,

- filling gaps,

- risk of breakage.

Plastic injection molding at Altyor

We have a workshop at our Altyor Shanghai plant, and a network of injectors in France and Europe.

Our Shanghai workshop can inject a wide variety of materials: ABS, PC, PP, PA, etc.

tonnages from 80 to 500 t

Designing a high-performance mold: the heart of the project

The mold is not just a tool: it is the industrial DNA of your product.

A well-designed mold ensures uniform filling, optimal cooling, and a controlled cycle.

Injection points, cooling, vents: the three key areas

The injection point determines the aesthetics and quality of the filling.

Poor positioning creates unbalanced flows, visible weld lines, or poorly filled areas.issage.

Un mauvais positionnement crée des flux déséquilibrés, des lignes de soudure visibles ou des zones mal remplies.

The cooling system stabilizes the material during cooling. Irregular cooling causes internal stresses.

Vents remove air. If they are poorly positioned, they cause burns or dry spots.

Choosing the right type of mold for your needs

The choice of mold is never a default choice. It is a strategic decision that depends on several technical and economic criteria. Each project, each series, and each material imposes its own constraints.

Here are the main factors to consider before determining the appropriate type of mold:

- The expected production volume

- The expected level of accuracy

- The geometric complexity of the part

- The type of material used

- The initial tooling budget

- The desired service life of the mold

For a more comprehensive overview of mold types (multi-cavity molds, family molds, hot/cold runners, aluminum molds, steel molds), you can consult this very comprehensive resource: Compare mold types in 5 minutes

Why does the mold influence the cost of the part?

Because the mold determines the stability of the cycle.

A high-performance mold reduces rework, scrap, and downtime.

It is often more cost-effective to invest in a high-quality mold than to compensate for defects with additional machine time.

How to master the plastic injection process

A good part also depends on machine settings.

Injection molding requires precise control of parameters to ensure consistent quality.

Pressure, speed, temperatures: the settings that change everything

The material must flow correctly into the mold.

Too little pressure leaves unfilled areas.

Too much pressure can create internal stresses.

The injection speed influences the surface finish and the way the material conforms to the mold.

The plasticizing, mold, and holding temperatures must be adjusted to prevent material degradation.

Optimize the injection cycle to reduce costs

The injection cycle directly influences the unit cost.

An optimized cycle allows for faster production without sacrificing quality.

It is a delicate balance between productivity and defect control.

Prevent material degradation

Some materials do not tolerate prolonged heating times or shearing well.

Incorrect settings can make the material brittle or unstable.

This is particularly important for recycled plastic, which must be handled with care to preserve its properties.

Validate, test, and ensure reliability: the key to controlled production

Before launching the series, the part must be tested, proven, and validated.

Mechanical, dimensional, and aging tests

The tests ensure that the part meets the specifications.

They reveal:

- weaknesses,

- deformations,

- thermal issues,

- dimensional variations.

The most successful projects are those where teams take the time to adjust.

When should you switch to series?

When:

- defects are under control,

- the material behaves as expected,

- the cycle is stable,

- the parts are compliant.

Industrial serenity depends on this step.

How to successfully industrialize your connected object?

Industrialization is a key stage in the development and production of an electronic product. In this guide, our experts have put together 16 key points to help you understand what’s at stake in this phase.

Plastic injection molding remains one of the most reliable processes for manufacturing plastic parts. Choosing the right material, optimizing the design, thinking through the mold in detail, and mastering the injection process are all factors that contribute to obtaining precise, attractive parts that are suitable for real industrial use.

Each project is unique. Some prioritize mechanical strength, others focus on appearance, durability, or environmental impact. But all benefit from a rigorous approach and constant dialogue between design and production.

At Altyor, this integrated vision guides our work: supporting companies in transforming an idea into a product that can be industrialized, is reliable, and is consistent with their market ambitions.

👉 Do you have a hardware concept? We turn it into an industrialized, tested product that is ready for mass production.