What is the role of a mechanical design office?

The three words that make up the name of this type of department sum up its role perfectly. A mechanical design office brings together specialists whose job it is to study, design to given specifications and propose solutions.

In practical terms, a mechanical engineering department is tasked by a customer with thinking up and developing a product, whether it’s a mechanical sub-assembly or a machine, for example. To carry out this mechanical engineering work, mechanical design teams study their customer’s business, needs and objectives. They also take into account the constraints imposed on them, whether in terms of human and/or material resources, skills, etc. They must also take into account the financial and other constraints imposed by the customer.

Translated with DeepL.com (free version)

At the end of this mechanical engineering work, the office delivers a file containing drawings and data on the performance, strength, design and cost of the final product.

Why work with a mechanical design office?

Les raisons sont multiples, qui peuvent inciter une entreprise à externaliser sa R&D. Recourir à des services extérieurs revient en effet à confier à un partenaire des travaux de recherche et développement. Ce recours peut notamment s’expliquer par un manque de compétences techniques spécifiques, en interne, pour mener à bien certains travaux.

This is particularly the case if the RD requirement is a punctual one. In such cases, it is not worthwhile for the customer to develop these skills and set up a new team. This is all the more the case given that such an approach sometimes requires significant investment, and necessarily takes time. And yet, the customer’s needs may be urgent.

In another case, the skills are available in-house, but can’t be mobilized for lack of time. In this case, it is necessary to transfer the extra workload to others. The company may also feel the need to adopt a different approach, to take advantage of another way of designing differently”, of solving a problem. A human community, in this case a company, often benefits most from an outside perspective. Outsourcing RD can be a good opportunity to benefit from this “fresh eye”.

When does the mechanical engineering department become involved in a project?

A mechanical design office is involved right from the start of a project. The first step is to precisely define the customer’s needs. We then draw up a set of specifications, which will serve as a reference, a “bible”, throughout the project.

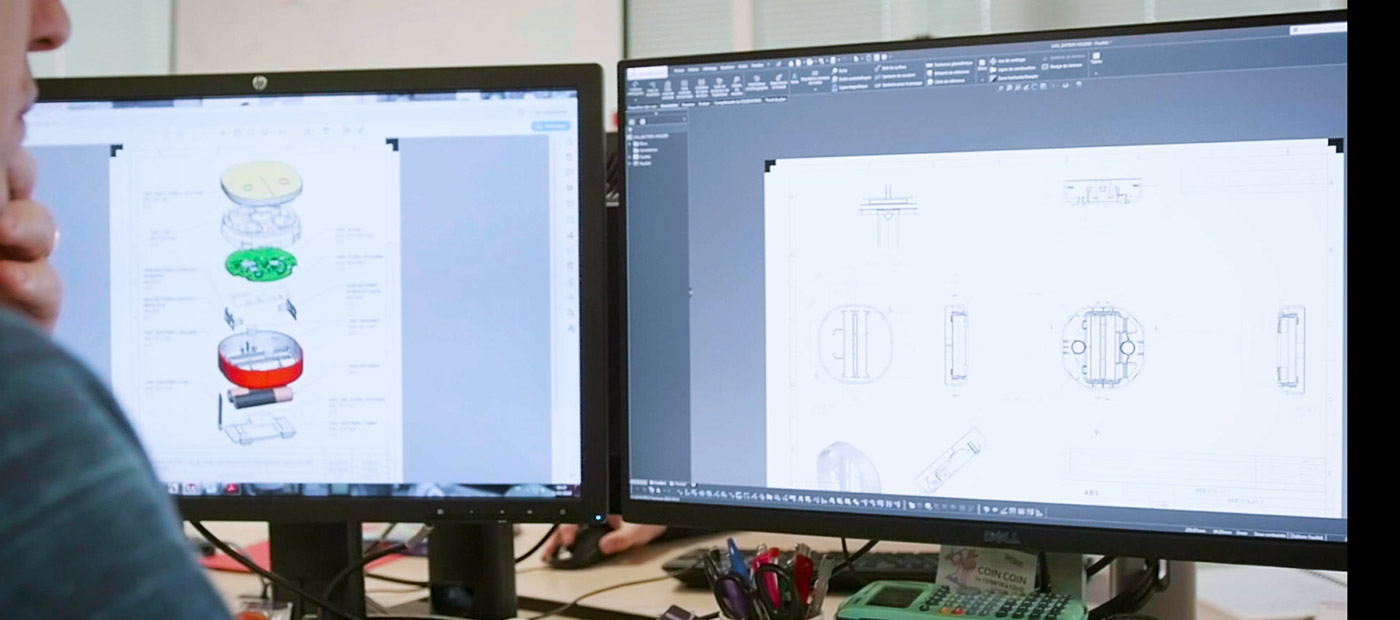

La phase de conception, via des outils comme la CAO (Conception assistée par ordinateur), permet ensuite de donner virtuellement vie au produit. Les étapes suivantes consistent, par étapes successives, à passer du virtuel au concret, au produit physique. La première d’entre elles est le prototypage, c’est-à-dire la réalisation de prototypes. Il s’agit de valider les étapes précédentes de conception. Puis arrive, en fin de projet, la phase d’industrialisation — Pilot Run, Serial Run —, grâce à laquelle le futur processus de production en série est verrouillé.

From upstream to downstream, from drawing up specifications to production, via CAD, prototyping and industrialization, the mechanical engineering department is involved in all stages of product development.

Altyor, a pioneer in eco-design

Chez Altyor, le bureau d’études mécanique est constitué d’une dizaine d’ingénieurs multi-compétences et répond aux différents besoins des clients : de l’expression du besoin à la conception. Précurseur grâce à notre démarche Design for Tomorrow, notre bureau mécanique réalise de l’éco-conception, c’est-à-dire développe chaque produit avec une vision éco-responsable. C’est, par exemple, une vigilance dans l’utilisation des matières (notamment la matière plastique recyclée via notre filière de recyclage) ou encore des procédés d’assemblage (pour optimiser le démantèlement des produits pour leur revalorisation).

Trained as an engineer, Damien started at Altyor as a mechanical engineer in product design in 2005, then became head of the mechanical design office in 2009 and, since 2019, RD director and leader of the management committee.Damien has all the qualities of a manager: technical expertise, global vision, listening skills and passion. His ability to work on a wide range of subjects and his commitment to customer satisfaction make him a key player at Altyor.

Damien is keen to pass on his experience and unite teams to take on major challenges.

With his industrial design diploma in hand, Olivier joined Altyor. Since 2007, his passion, creativity and challenges have led him from a specialization in design to expertise in plastics processing. Olivier is ingenious, with the soul of an explorer, he enjoys discovering how products work and, above all, helping customers bring their ideas to fruition. Since 2019, Olivier has been in charge of Altyor’s mechanical design office. Persevering, he masters both design and technology, which enables him to support his team on a daily basis to lead them to success. His daily driving force is to see things through to the end, not to give up, and to achieve the impossible.

Romuald graduated in 1999 with a BTS in mechanical production engineering. For 11 years, he worked as a design draughtsman, before joining Altyor in 2012 as a mechanical project manager. With over twenty years’ experience, he is an important asset to Altyor’s mechanical design office. His skills range from the design of multi-material products to the development of assembly tooling and the study of mobile systems, motors, cylinders and transmissions. Romuald’s experience enables him to support and share his knowledge with teams and customers alike.

3 design examples

produced by our mechanical engineering department

Aveine smart wine aerator

Altyor is Aveine’s industrial partner, from electronic and mechanical design to aerator production.

Pour concevoir cette innovation, ce sont des compétences multi-technologiques qui ont été nécessaires. Notre bureau d’études mécanique a intégré un écran et un touchpad spécifique. L’expertise en mécanique des fluides et sur les procédés pour l’étanchéité a également été nécessaire. Tout cela en respectant les normes liées au secteur de l’alimentaire.

Connected wristband from Ido Data

In addition to mechanical design, Altyor was responsible for electronic design, industrialization and production.

While the technical challenges in electronics were significant (miniaturization vs. radio performance, autonomy, etc.), the mechanical challenges were real issues for this product. First of all, the user experience was central, notably in terms of the haptic feedback from the button, the ergonomics of triggering the alert and the comfort of the bracelet (touch, wrist size, etc.). Finally, the constraints of the product environment (sun, salt water, etc.) also had an impact on the design by the mechanical engineering department.

Osmose from Expressive E

Osmose is the latest instrument launched by start-up Expressive E. A revolutionary digital keyboard synthesizer! In terms of design, the challenges were many for our mechanical engineering department (especially with over 500 parts!):

L’autre défi pour un produit si complexe a été la volonté de développer un produit éco-conçu, notamment sans adhésif, sans colle, et l’utilisation de matière recyclée à hauteur de 80% lors de la fabrication.

How to design a successful connected object?

Mechanical and electronic design is the first major step in your product journey. It will lead you to the prototyping, industrialization and production phases. In this guide, you’ll discover 18 key points for designing your connected object.

Our programs to suit your needs

UnLock program

Need help defining the specifications for your connected product?

LaunchPad program

Do you need to design and produce

functional prototypes?

ScaleUp program

Do you need to design and manufacture

your connected object?

Infinity program

Want to give your product a second life

your product through a circular economy loop?