Industrialization, a key issue for successful manufacturing

Industrializing your products,

our expertise

From a finished prototype, we design,

make reliable and put into production

all the tooling, assembly lines and test benches required

for serial production.

A key step in securing your production

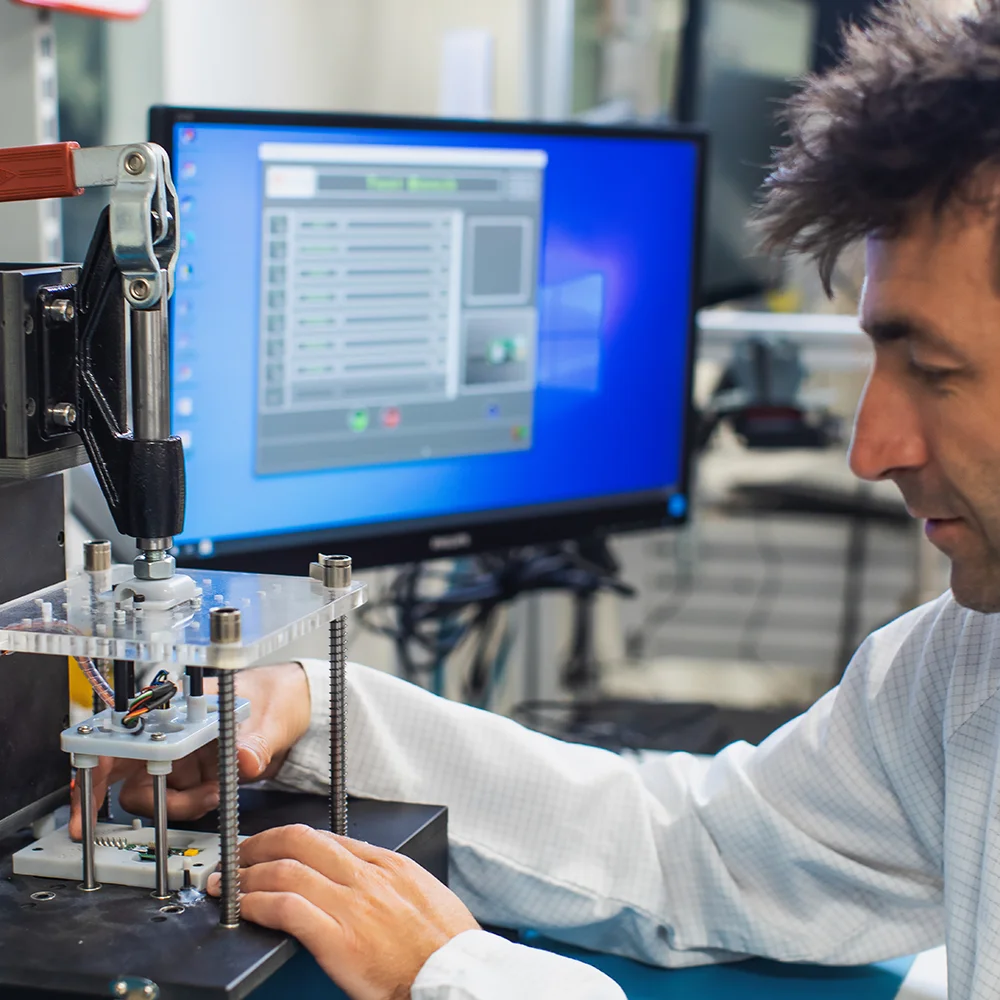

Industrialization is a key stage in the development and production of an electronic product. It includes :

The manufacturing file, a central deliverable for industrialization

From the very first component placements, routings and designs, we apply our industrial methods to guarantee a reliable product – this is what we call Design for Manufacturing. All the DFMs (parts drawings, electronic board definitions, overall drawings) form the basis of this manufaturing file.

It also includes assembly instructions, workshop layout and quality control specifications for robust assembly lines and optimal ramp-up.

From this deliverable, our teams will launch the first iterative production stages. With each iteration, your production becomes more mature and reliable, and your production department begins to produce in large quantities.

Get a quote tailored to your project!

Designing and manufacturing your molds and tools

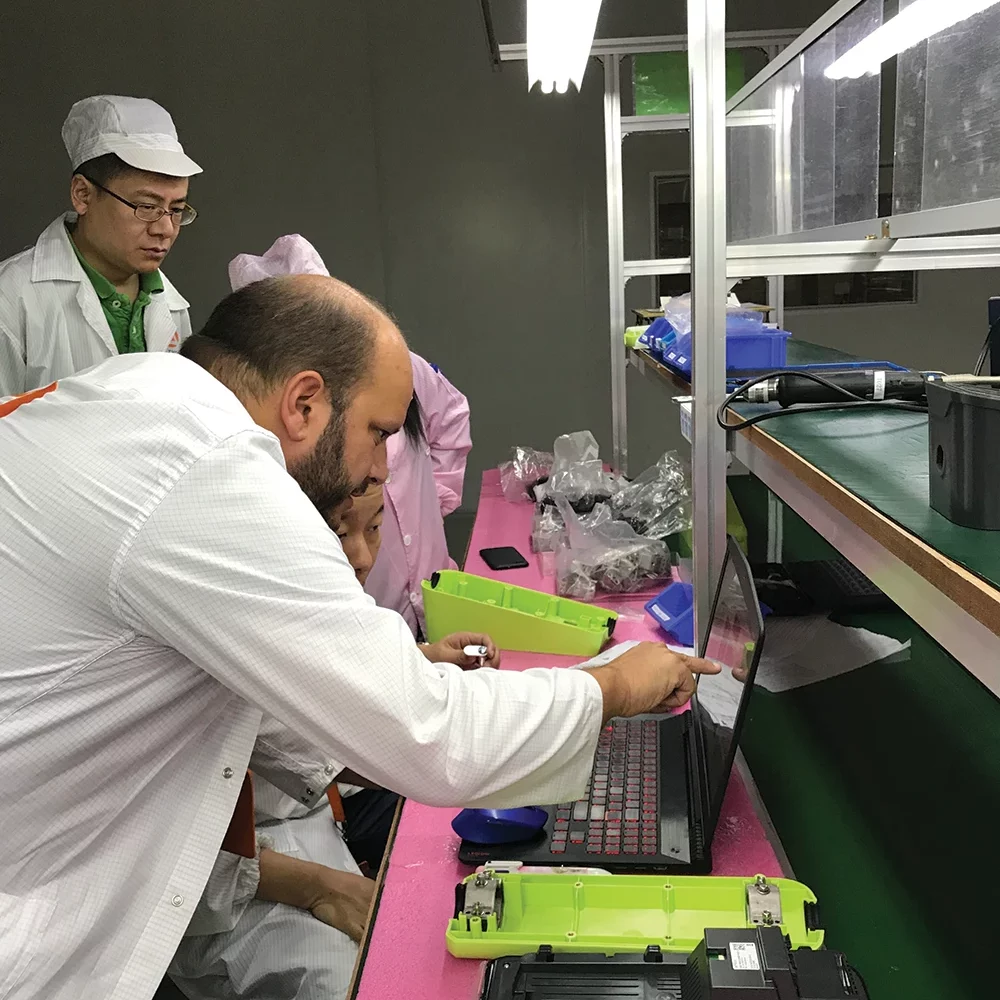

Expert en conception de pièces plastiques, force de propositions en matériaux et procédés, Altyor dispose d’un large savoir-faire dans la transformation des matières (plastiques, silicone, métal, etc.).

Nous avons conçu et fabriqué des moules pour des centaines de clients. Nous disposons de solutions sur-mesure, en nous appuyant sur des moyens industriels intégrés ou en sous-traitance, en Europe ou en Chine.

The choice of transformation processes (injection, compression, extrusion, machining, stamping, marking, surface treatment and finishing, etc.) is adapted to the mechanical, functional, aesthetic and normative requirements of our customers and sized to best suit the quantities to be manufactured.

Qualification, pre-certification and certification

Once the first products have been assembled, Altyor qualifies the product according to the qualification plan drawn up at the design stage, and pre-certifies the product using our integrated tooling. The aim of qualification and pre-certification is to ensure compliance with the requirements of the standards required for its use.

Final certification is carried out by a notified body, with monitoring and support from Altyor, using products from the initial production phases.

Our programs to suit your needs

UnLock program

Need help defining the specifications for your connected product?

LaunchPad program

Do you need to design and produce

functional prototypes?

ScaleUp program

Do you need to design and manufacture

your connected object?

Infinity program

Want to give your product a second life

your product through a circular economy loop?

How to successfully industrialize your connected object?

Industrialization is a key stage in the development and production of an electronic product. In this guide, our experts have put together 16 key points to help you understand what’s at stake in this phase.