Production tooling, guaranteeing robust assembly

Test benches, molds, assembly jigs…

Essential “extras”

Industrialization is essential to prepare for high-volume production. The design and manufacture of production tooling are part of this stage, and will enable you to create your parts or guarantee a safe increase in output.

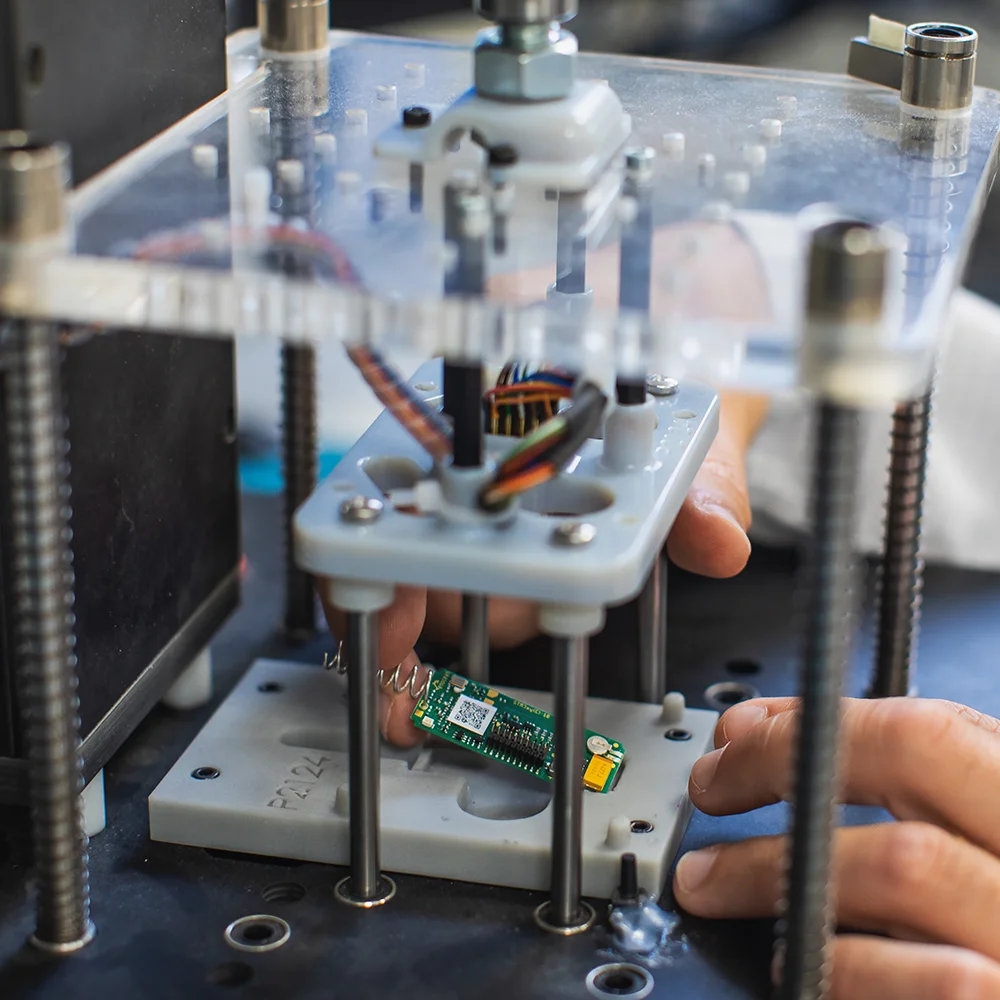

Test benches for 100% functional products

A test bench will be used to test the integrity of the electronic board and the correct operation of the product. Altyor benefits from this expertise not only in the mechanical manufacture of the test bench, but also in the development of the firmware. Within our assembly lines, 100% of products manufactured pass through the test bench stage, ensuring consistency and guaranteeing that your products sold will be faultless.

Translated with www.DeepL.com/Translator (free version)

There are 2 test benches:

The test bench also enables firmware to be flashed into the product.

Moulds for your parts

Some processes require a mold. This is the case with plastic injection molding, for example: the mold is used to mass-produce one or more plastic parts. Each mold requires considerable design and production time (8 – 12 weeks).

A mold is made up of one or more cavities, allowing a production capacity consistent with the volumes of the finished product. It’s a technically complex element from a mechanical point of view, which explains its high cost (from a few thousand to tens or even hundreds of thousands of euros).

Can we help you with your project?

Assembly jigs and steel masks

Assembly jigs are mechanical tools designed to facilitate and optimize the assembly of a mechanical sub-assembly. They are also designed to prevent assembly errors (poka-yoke).

The steel mask is positioned between the printed circuit board (PCB) and the solder paste. It’s an open-work mask, enabling solder paste to be deposited at component soldering points. It’s the same principle as screen printing.

How to successfully certify your connected object?

Certification is a prerequisite for bringing your product to market. This guide contains 15 questions and answers to help you understand this final step.